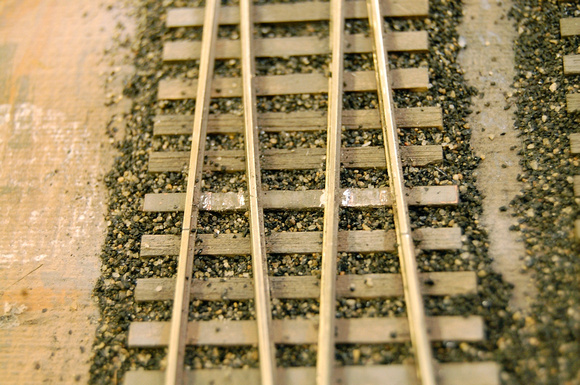

I removed most of the foil from some of the turnouts for a couple of reasons described below. The result was inconsistent powering of the diverging rail. The diverging rail was just long enough that an 0-6-0 and tender could sit between the point and frog (which are powered). If the point wasn't hard against it's stock rail, the locomotive stalled.

The fix was to remove paint and apply wire jumpers.

Reasons I removed the foil (and reasons not to do it following) were:

- Initially, I started with a slightly wider wider notch in the foil to ensure I would have no shorts. I had one turnout in which the single notch (common practice) left just the tiniest amount of foil uncut, leading to a short that was tough to find.

- This led to the idea that a wider gap would also be less visibly noticeable than a notch.

- This grew further into the idea that removing all the foil except that near the rail would allow the remaining foil to represent a tie plate.

This was a failure, don't do it!

- The remaining foil's grip on the PC board can fail (this occurred).

- It leads to stupid mistakes such as removing foil where you want continuity - e.g. between the stock and diverging rail. This leaves electrical continuity dependent upon consistent point / stock rail contact. The turnout pictured was not consistent.

- It's a lot of work

- It doesn't look good (at least with my method of using a dremel cutting wheel to "grind" the foil off)